- Equipment

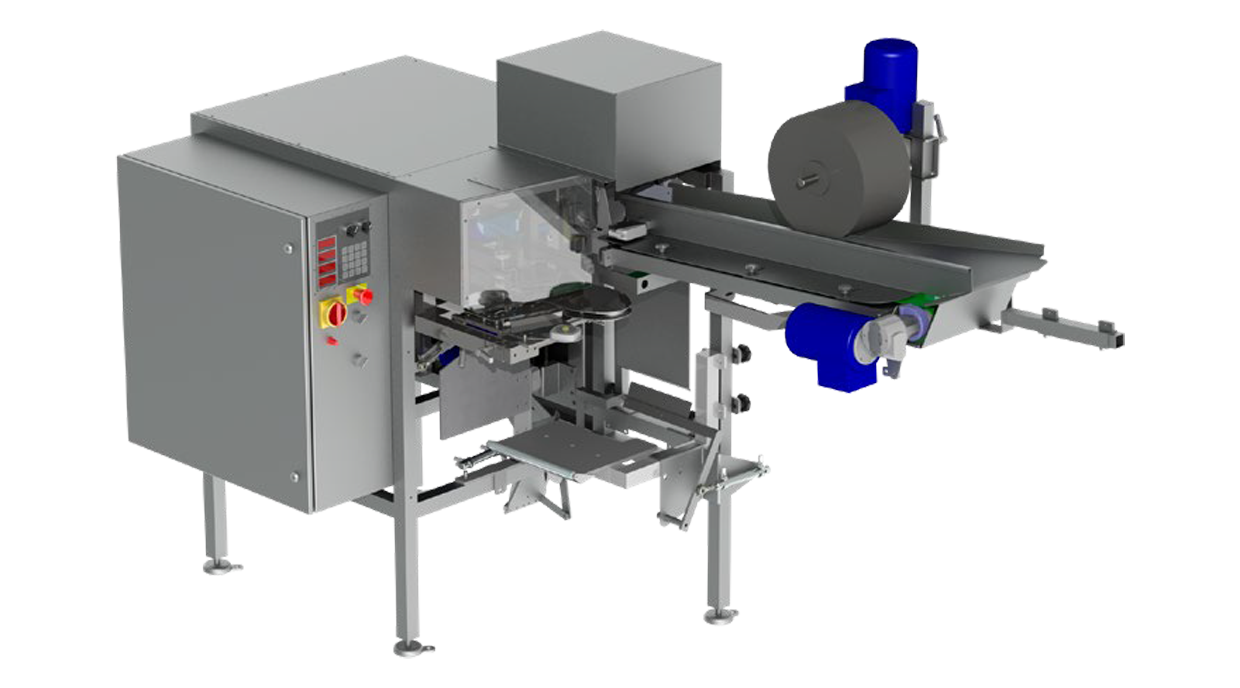

- NEWTEC PEB40 KL

NEWTEC PEB40 KL

NEWTEC PEB40 KL

Details

Key Features and Benefits

- Full stainless-steel construction

- Bag pull-up and tension feature to tighten bag before application of Kwik-Lok

- Multiple printer choices available for Kwik-Lok bag closers

- Available as Combi machines to use tape and Kwik-Lok closers on the same bagger

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Works With

Pears

Pears

Details

Key Features and Benefits

- Full stainless-steel construction

- Bag pull-up and tension feature to tighten bag before application of Kwik-Lok

- Multiple printer choices available for Kwik-Lok bag closers

- Available as Combi machines to use tape and Kwik-Lok closers on the same bagger

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Downloads

Technical Specs

Speed

Up to 25 bags per min.

Capacity

Weight up to 5 kg

Bag size

H=300mm-550mm

W=220mm-320mm

Material

According to the EU rules on

food contact materials

Air Connection Requirement

3/8”

Air Minimum Pressure Requirement

6 bar (0.6 Mpa)

Air Consumption Requirement

130 NL/min.

Electrical Requirement

3×230 VAC or 3×400 VAC (N)

PE 50/60 Hz 1 kW

Environment

5ºC–40ºC

Weight

320 kg

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

Automatic wicket baggers recommended for Kwik-Lok closures are packaging machines designed to work seamlessly with Kwik-Lok closures, a type of reclosable fastener commonly used for bagged products. Kwik-Lok closures are widely used in the food industry to provide a convenient and secure way to reseal bags, maintaining product freshness and extending shelf life. Automatic wicket baggers that are compatible with Kwik-Lok closures offer efficient and precise bagging operations. Here are some features and considerations for such baggers:

- Integration with Kwik-Lok Closure Systems:

- These baggers are specifically designed to integrate with Kwik-Lok closure systems. The machinery is configured to handle the application of Kwik-Lok closures to the bags during the packaging process.

- Accurate Placement of Kwik-Lok Closures:

- The bagging machine is equipped with mechanisms to ensure accurate and consistent placement of Kwik-Lok closures on the bags. This precision is crucial for reliable and effective closure application.

- High-Speed Operation:

- Automatic wicket baggers recommended for Kwik-Lok closures are often designed for high-speed operation to meet the demands of large-scale packaging operations. This is especially important for maintaining productivity in fast-paced manufacturing environments.

- Adjustable Settings:

- The bagging machine typically features adjustable settings to accommodate different bag sizes, product types, and closure specifications. This flexibility allows for customization based on specific production requirements.

- Wicketed Bag Dispensing:

- Wicketed bag dispensing is a common feature in these machines. Bags are mounted on a wicket for easy loading onto the bagger, ensuring a continuous and efficient bagging process.

- User-Friendly Interface:

- The bagger is equipped with a user-friendly interface that allows operators to set parameters, monitor the bagging process, and make adjustments as needed. This simplicity enhances ease of use and operational efficiency.

- Integration with Other Equipment:

- Automatic wicket baggers recommended for Kwik-Lok closures can be integrated into larger packaging lines, allowing for synchronized operation with other equipment such as weighers, fillers, and conveyors.

- Durable Construction:

- These machines are constructed with durability in mind to withstand the demands of continuous production. Robust construction contributes to reliability and longevity.

- Compliance with Industry Standards:

- The bagging machine is designed to comply with industry standards related to hygiene, safety, and quality. This is particularly important in food packaging applications where strict regulations are in place.

- Versatility for Different Products:

- The versatility of the bagger allows for packaging various products, including fresh produce, snacks, baked goods, and other items that benefit from the use of Kwik-Lok closures.

- Quality Control Systems:

- Some machines may incorporate quality control systems to ensure the proper application of Kwik-Lok closures, minimizing errors and enhancing overall product quality.

By selecting an automatic wicket bagger recommended for Kwik-Lok closures, manufacturers can benefit from an integrated and efficient packaging solution that incorporates the advantages of Kwik-Lok reclosable fasteners for their bagged products.

Automatic wicket baggers recommended for Kwik-Lok closures offer several benefits, enhancing the efficiency and convenience of bagging operations in the food and packaging industry. Here are key advantages associated with these specialized bagging machines:

- Precise Closure Application:

- These baggers ensure accurate and consistent placement of Kwik-Lok closures on bags. This precision is crucial for effective sealing, maintaining product freshness, and preventing leaks or spills.

- Increased Productivity:

- Automatic wicket baggers are designed for high-speed operation, contributing to increased productivity in bagging processes. The automation of closure application and bag filling reduces manual labor requirements, allowing for efficient large-scale production.

- Efficient Wicketed Bag Dispensing:

- Wicketed bag dispensing is a feature that streamlines the loading process. Bags are mounted on a wicket for quick and easy loading onto the bagger, ensuring a continuous and efficient bagging workflow.

- Customization for Different Bag Sizes:

- The baggers typically come with adjustable settings, allowing operators to customize the machine for different bag sizes. This flexibility accommodates various packaging needs and product specifications.

- User-Friendly Interface:

- Equipped with a user-friendly interface, these bagging machines make it easy for operators to set parameters, monitor the bagging process, and make adjustments as needed. This simplicity enhances ease of use and reduces the learning curve for operators.

- Integration with Other Packaging Equipment:

- Automatic wicket baggers can be seamlessly integrated into larger packaging lines. This integration allows for synchronized operation with other equipment, such as weighers, fillers, and conveyors, optimizing the overall packaging process.

- Reduced Labor Costs:

- Automation of the bagging process leads to a reduction in manual labor requirements. This not only increases efficiency but also contributes to cost savings by minimizing the need for additional labor.

- Durability and Longevity:

- These baggers are constructed with durability in mind to withstand the demands of continuous production. Robust construction contributes to the longevity of the machine, reducing maintenance requirements and downtime.

- Compliance with Hygiene and Safety Standards:

- Automatic wicket baggers recommended for Kwik-Lok closures are designed to comply with industry standards related to hygiene, safety, and quality. This is crucial, especially in the food industry where stringent regulations are in place.

- Versatility for Different Products:

- The versatility of these bagging machines allows for packaging various products, including fresh produce, snacks, bakery items, and more. The use of Kwik-Lok closures enhances the convenience of reclosing and resealing packaged items.

- Quality Control Systems:

- Some machines may incorporate quality control systems to ensure that Kwik-Lok closures are properly applied. This minimizes errors in the packaging process and enhances the overall quality of the final product.

- Improved Product Freshness and Shelf Life:

- Kwik-Lok closures provide an effective reclosable seal, preserving the freshness of the packaged products. This is particularly beneficial for items that consumers may consume over multiple sittings, contributing to an extended shelf life.

Automatic wicket baggers recommended for Kwik-Lok closures offer a combination of precision, efficiency, customization, and integration capabilities, making them valuable assets in packaging operations where reliable closure application is essential.

An automatic wicket bagger recommended for Kwik-Lok closures is versatile and suitable for packaging various types of fruits and vegetables. The reclosable nature of Kwik-Lok closures makes them ideal for preserving the freshness of produce over multiple uses. Here are examples of fruits and vegetables commonly bagged using such automatic wicket baggers:

- Berries:

- Strawberries

- Blueberries

- Raspberries

- Blackberries

- Grapes:

- Red grapes

- Green grapes

- Seedless varieties

- Cherries:

- Sweet cherries

- Sour cherries

- Stone Fruits:

- Peaches

- Nectarines

- Plums

- Citrus Fruits:

- Oranges

- Mandarins

- Lemons

- Limes

- Apples:

- Small-sized apple varieties

- Pears:

- Small-sized pear varieties

- Kiwi:

- Kiwifruit

- Melons:

- Cantaloupe

- Honeydew

- Pineapple:

- Pineapple chunks or slices

- Bananas:

- Small-sized or baby bananas

- Tomatoes:

- Cherry tomatoes

- Grape tomatoes

- Bell Peppers:

- Mini bell peppers

- Cucumbers:

- Baby cucumbers

- Carrots:

- Baby carrots

- Radishes:

- Mini radishes

- Zucchini:

- Baby zucchini

- Broccoli:

- Broccoli florets

- Cauliflower:

- Cauliflower florets

- Snap Peas:

- Baby snap peas

- Green Beans:

- Baby green beans

- Asparagus:

- Thin asparagus spears

- Brussels Sprouts:

- Baby Brussels sprouts

- Mushrooms:

- Small-sized mushrooms

- Leafy Greens:

- Baby spinach

- Baby kale

- Fresh Herbs:

- Cilantro

- Parsley

- Basil

- Avocado:

- Sliced or diced avocado

- Radishes:

- Baby radishes

- Microgreens:

- Various microgreen varieties

- Mixed Vegetable Packs:

- Assorted vegetable packs containing a combination of small-sized vegetables

These examples represent a diverse range of fruits and vegetables that can benefit from the use of Kwik-Lok closures and the efficient packaging provided by automatic wicket baggers. The reclosable feature of Kwik-Lok closures helps consumers maintain the freshness of the produce after opening the bag, making them suitable for a wide range of fresh and pre-packaged items.